The UIAA Safety Commission has held its annual plenary session from June 2 to 4 in Longarone, Italy.

The expert panel, which develops the safety standards for equipment recognized by climbers around the world, discussed the extent which approved testing facilities can subcontract their work as well as updates to various standards.

Also on the agenda was the issue of corrosion of anchors in tropical, marine areas.

The UIAA reported in October 2009 that anchors used on routes in these environments weakened due to corrosion caused by the sea and year round wet climates.

It was found that 10 to 20 per cent would fail with a force of 1 to 5 KN applied. The Safety Commission will discuss minimum lifetime targets for anchors in marine environments, choosing a corrosion resistant material, and recommendations for anchors already in place.

Braking

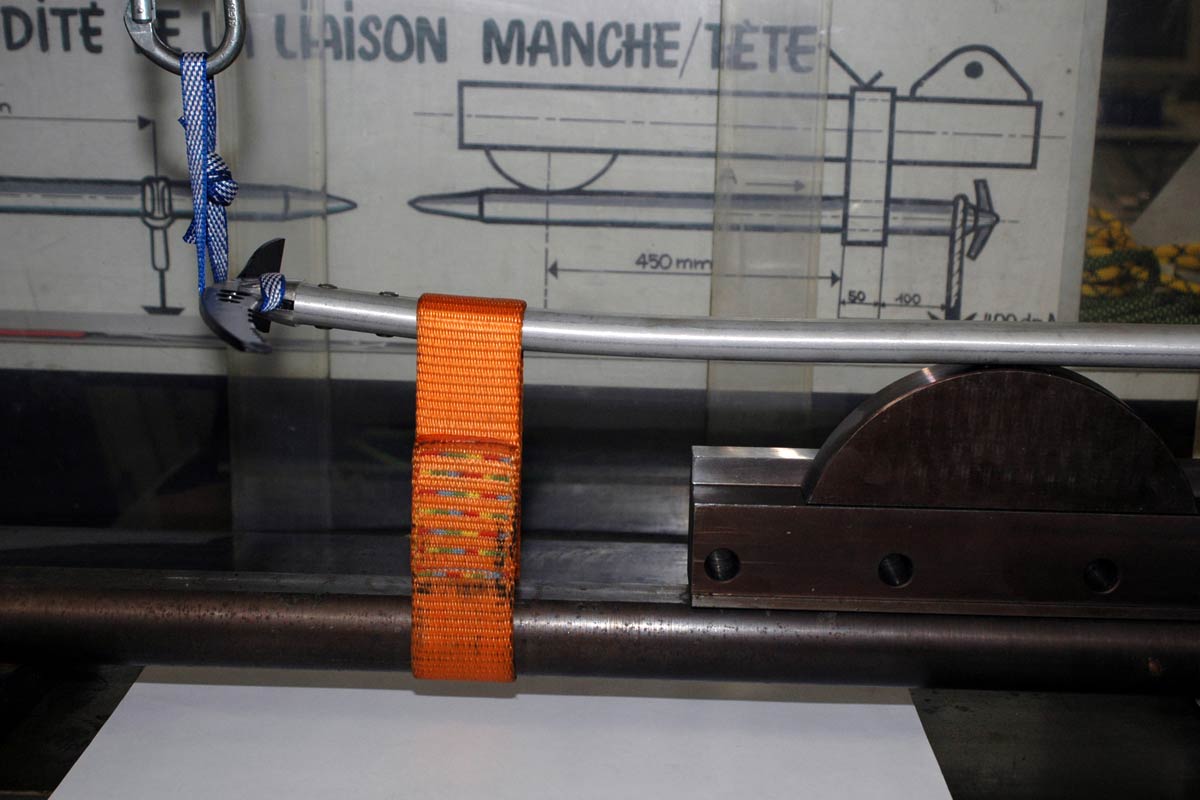

Minor changes to the new Braking Devices standard, which was the first of its kind when it was published in September 2009, were expected to be adopted in Longarone.

The standard deals with four kinds of braking devices: manual, locking-assisted, abseiling devices and abseiling devices with a panic function. It lays out how to conduct static strength tests to assess stress on both the rope and the braking device.

The president of the Safety Commission, Jean-Franck Charlet, lead a discussion on the EN standard on strength and slipping for crampons.

The Italian Alpine Club (CAI) backed a proposal to revive sharp edge rope tests, which were suspended a few years ago. This issue will be looked at by manufacturers, labs and commission members this year.

Numerous standards

There are currently 20 UIAA Safety Standards, ranging from helmets, ice tools and slings to pulleys, anchors and karabiners. The standards are used by many of the biggest manufacturers of mountaineering equipment.