Following recent profiles on the progress made by two past UIAA Mountain Protection Award winners – Mountain Wilderness France (2016) and AlpineLearning Project Weeks (2019) – the focus turns to 2017 winner Mount Everest Biogas Project (MEBP).

The United States-based project, launched in 2010, is a volunteer-run, non-profit organisation that has designed an environmentally sustainable solution to dealing with the impact of human waste on Mount Everest and eventually other high altitude locations. This year was set to witness significant on-site progress on Everest but the Covid-19 pandemic, as detailed below, has caused significant hold-ups.

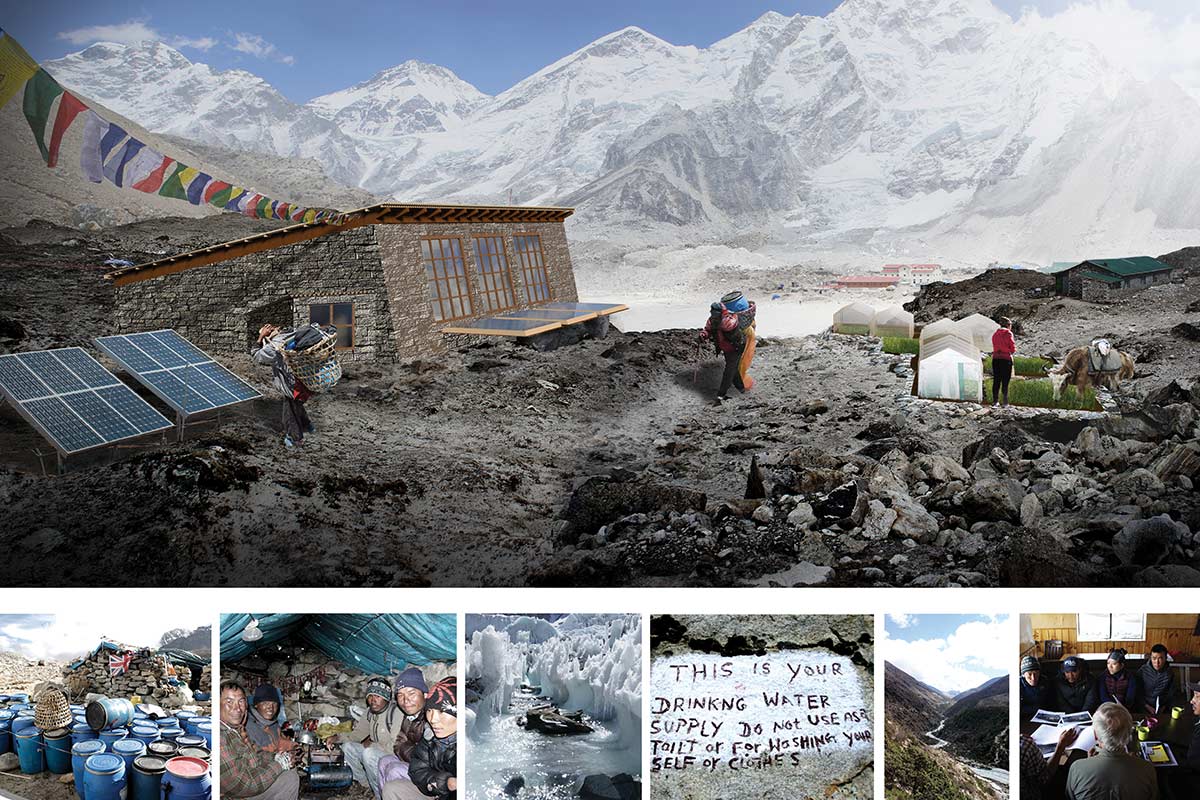

Mount Everest boasts a massive climbing industry, with hundreds of climbers – and support staff – make the trip up the Khumbu Valley each year (2020 being an obvious exception). This tourism has left a trail of human waste, approximately 12,000kg per year, that has given way to environmental and public health concerns. MEBP’s proposal is to use an anaerobic biogas digester to treat human waste. It will eliminate the dumping of solid human waste and destroy pathogenic fecal coliforms that threaten the health of the local communities – lessening the impact of the tourism industry on a mountain that is sacred to the Nepalese.

The Mt. Everest Biogas Project was designed to address this environmental and health hazards in a sustainable manner and serve as a model for other regions that must deal with similar waste problems at high-altitude, regardless if it is caused by climbers or local communities. The system will convert waste into methane, a renewable natural gas, and a reduced pathogen effluent.

Following the project’s MPA win in October 2017, groundbreaking for the biogas digester was planned for spring 2018 and an operational date slated for winter 2019, early 2020. The UIAA caught up with Dr Daniel Mazur, head of the project, to assess progress made during the past few years and in particular the impact of Covid-19.

UIAA: How much of a boost to the Mount Everest Biogas Project was winning the 2017 Mountain Protection Award?

MEBP: The Award brought recognition from an established international organisation, providing the MEBP with much welcome exposure as a legitimate development project for all those familiar with the UIAA. This has broadened our project’s recognition, and encouraged donor’s trust.

Can you briefly summarise how the project has evolved since 2017?

In 2018 we fully vetted our design, travelling to Nepal and signing Statements Of Work (SOW) with all the Nepali subcontractors we will work with to build the system. These SOW detail the scope of work for the subcontractors to accomplish and the cost expected at that time. So at this time we have all the required Nepali subcontractors lined up to start construction, and we have approval by the local government authorities to build within the Mt. Everest National Park. We have been working with Kathmandu University on a biogas research component for proof of design.

What sort of testing has been taking place?

Research undertaken by MEBP and Seattle University (SU) financed a second round of digester experiments at Kathmandu University in 2018. This research supported an MSc student, Mina Pokhrel. The pilot scale tests used blue barrel waste and were operated at mesophilic temperatures (25-30 C). The tests demonstrated biogas production in all four replicates.

The University of Washington and SU collaborated to analyse the microbial ecology of BSP type digesters in Nepal. This work was presented as a poster at the AEESP (Association of Environmental Engineering and Science Professors) conference and is currently being prepared for publication. BMP tests are being conducted at SU to determine the impacts of antibiotics commonly used by climbers on biogas production. Current results indicate little to no impact of the antibiotics. BMP tests are being conducted at SU to identify biodegradable bags that can be used to collect the waste, avoiding the need to macerate them prior to adding into the digester. Three tests have been completed with all bag types showing poor biodegradability. Four new bag types are currently being assessed.

How has your project been impacted by Covid-19?

Construction work in Nepal has been shut down by the Covid-19, stopping the possibility of building the MEBP anytime soon. The world economy has also contracted substantially because of this pandemic. This has slowed most donations to our project, and created a difficult fundraising environment where almost every country has a crisis and people are seeking funding from any source to survive through the year. Any help from UIAA, or its members, to find a funding sponsor would be greatly appreciated. The UIAA has dedicated an area of its donate page for the climbing community to help support the project.

During Covid-19, much of the groundwork in Nepal was put on hold. The team has taken this opportunity to sponsor an internship in the US for an aspiring engineer. This engineer has been working with the architect in the building of a physical construction model. That model will help work out construction sequencing and aid in communicating with the local builders, particularly in the details that are not standard in the local building traditions.

Regarding research, Kathmandu University is willing to start a new round of tests but we have to wait until the pandemic clears. Similarly at Seattle University, the students working with us can no longer work in the lab so that work is effectively on hold.

With access to the Nepalese mountains being restricted, were you nonetheless able to assure progress of your project?

Nepal is currently closed for most travel/construction. As soon as Nepal open from the pandemic, everyone will be hungry to get their industries back into motion. If we are able to fund the project at the time Nepal opens again then our Nepali subcontractors will certainly be happy to construct this project with us.

What are the priorities for the next twelve months?

As soon as Nepal opens and providing our fundraising efforts can continue, then we will finish building the project.

What is the risk that the project stops here and all the hard work over a decade comes to nothing?

From the standpoint of our own organisational (Board) members, the Mount Everest Biogas Project is going forward as the people involved are deeply concerned about this troubling issue. When the Everest climbing expeditions get going again, after Covid, there will be thousands of people using the toilets in base camp and their waste will once more be dumped in unlined pits near the Everest trail. This waste must be treated. The Biogas Project provides an elegant solution. Treat the waste, removing pathogens, and convert it into biogas cooking fuel and fertilizer. We are working very hard to try and raise the money, so that this problem can be solved. If we don’t solve it now, before it is too late, the pits will overflow even more than they are now and contamination will spread from Everest basecamp throughout the entire Khumbu Valley and further poison the Sherpa people and tourists, trekkers, and climbers visiting Everest. On another matter, we have all been working hard to line up all of the necessary paperwork, permits and supporters in the Nepal government and climbing community. This Nepal wide organisational support has been achieved. If for some reason, we are not able to raise the funds soon, then this support may erode as the government changes, and we might have to begin the process all over again, causing further delays and the tragedy of climbers and Sherpas and Nepalese staff’s untreated waste from Everest Base Camp could continue unchecked for many years to come.

What advice would you give to other organisations and/or UIAA members running similar sustainability-led projects? What makes a successful project?

Close coordination with the local people is key to selecting spaces, techniques and collaborators; so as to avoid crossing cultural taboos or overstepping the project’s invitation to alter the community, landscape or how things are done. We must strive to create development projects that address the specific requests of a community, instead of pushing preconceived “solutions” that may impose our culturally informed view of how things should be done. The MEBP is still on guard to avoid these pitfalls, as we continue to pursue implementation of our system for Gorakshep.

How can the general public support/mountaineering community support your project?

How can the general public support/mountaineering community support your project?

Donations to the project from climbers and the public are a very tangible way for people to support this project. But even sharing about our project through social media and other outlets helps to expand our project’s recognition and inch us closer to completing our fundraising goals. Thank you very much for your interest in helping to solve the human waste problem on Mount Everest. We greatly appreciate all that everyone at the UIAA is doing to take care of our world’s mountains!

FURTHER DETAILS

UIAA

UIAA Mountain Protection Award

Donate and support MEBP

Mount Everest Biogas Project

Home page

UIAA 2017 announcement

PROJECT PARTNER

Bally is a Swiss luxury brand established in 1851, with a rich heritage in shoemaking, and a longstanding relationship to architecture, arts and the environment. Today, the brand offers unique designs across shoes, accessories and ready-to-wear, driven by a dedication to craftsmanship and a contemporary aesthetic. Bally has over 300 retail stores and 500 multi-brand points of sale that span across 66 countries worldwide, including a global e-commerce platform serving 34 countries. For more information, please visit Bally.com

Photos and visuals by MEBP and Joseph Swain