The UIAA – International Climbing and Mountaineering Federation – Safety Commission (SafeCom) has published the following alert regarding canyoning harnesses.

Report of Failures

It was reported that three canyon harnesses of unrelated brands and models, broke between July 2017 and December 2018 in La Réunion as well as in two popular spots on mainland France, le Verdon and Angon. Fortunately, these breakages did not result in any serious injuries. The people involved in these incidents simply hanged in their harness on the belay and fell because the harness broke.

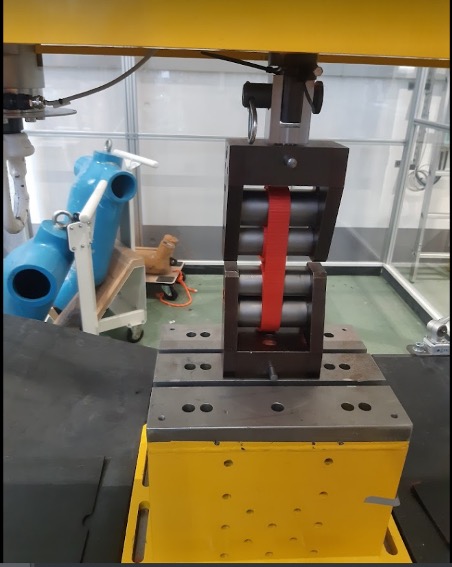

Testing Process

UIAA SafeCom asked two UIAA certified laboratories to conduct tensile tests on canyoning harnesses which were worn after professional collective use of a period of four years. Globally, the results showed a loss of resistance. This was from 20% to 90% of the standard resistance. The highest losses – i.e., more than 50 %, some broke at 150 daN – were systematically seen on harnesses worn by collective use. In terms of safety, this is simply not acceptable. On the other hand, harnesses used intensively in a dry environment, like in climbing gyms or while mountaineering, even through collective use, were not so severely impacted.

The results of this first study seem to prove that this could be a major safety issue. Consequently some complementary tests were organised to understand more about the influence of UV in the canyoning harnesses ageing process.

Two others certified SafeCom labs conducted UV-ageing tests on straps used in canyoning harness construction: polyamide, polyester and dyneema-polyamide materials were tested, up to 2,000 hours of ageing and in a chamber where the temperature can climb up to 70°C. Tensile tests on the UV aged samples were then conducted, to measure their residual resistance.

Test Findings

This study showed that:

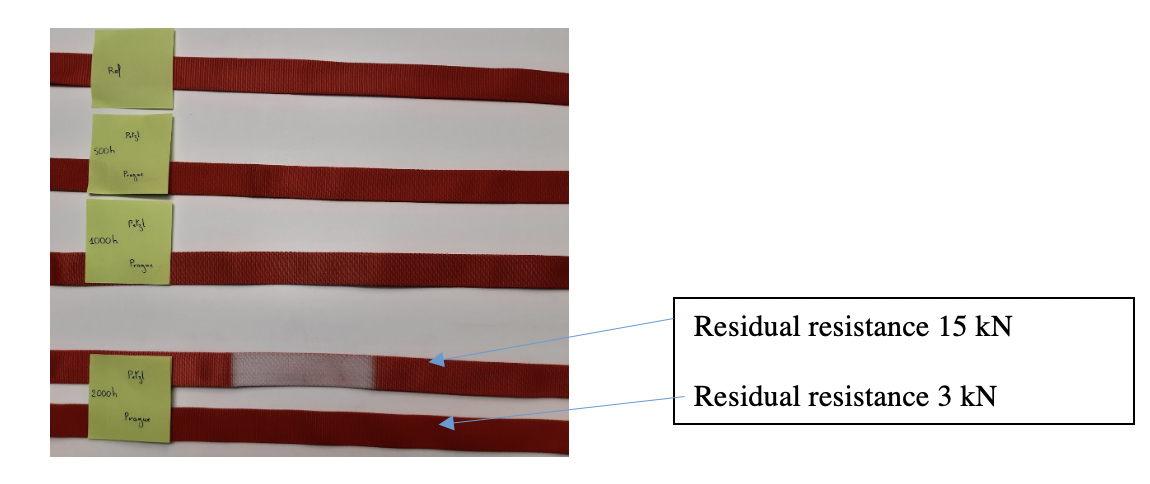

- The samples show an unequal discoloration after UV ageing, depending on how the sample is initially dyed, and that there is not any correlation between strap discolouring and their loss of strength.

Aspects and resistances of worn samples © Petzl - The UV conditioning leads to very significant losses in strength affecting some of the straps. The Dyneema/PA straps are the ones most impacted with a strength level that drops from 20 kN for the reference samples to 1kN in the most severe cases. Polyamide is also severely impacted: the resistance of some samples decreases from 30 kN to 3 kN after 2,000 hours of conditioning. Polyester is less sensitive than the previous materials to UV weathering.

- The components of the harnesses involved in incidents (see above) were made up of polyamide, a material especially impacted by UV weathering. Consequently, special care should be paid to product storage and drying conditions, taking care to best comply with the manufacturer’s recommendations and to avoid drying products in direct sunlight or behind windows (such as in a vehicle or a room).

- There is a lack of knowledge regarding the correlation between harnesses ageing in natural sunlight and straps ageing in the labs. The effect of the temperature is also not completely understood. Because pure mountaineering/climbing harnesses do not show this great loss of resistance, the influence of the conditions of drying the canyoning harnesses should play a major role.

Specific Advice for Canyoners

When repeatedly using harnesses in wet/damp conditions, it is strongly advised that the following recommendations are strictly adhered to:

- Follow the instructions and information of the manufacturer regarding the frequency of checks and the criteria for disposal (look at the instructions for use given with each harness, or on the manufacturer’s website).

- Do NOT dry the harness by exposing it to high temperatures, but slowly dry this equipment in a ventilated room, protected from light (not behind a window, or on a car’s roof).

– Respect the manufacturers’ instructions and information regarding the control/revision of the harness.

– Follow details on how to assess the lifespan given by harness manufacturer: never exceed this lifespan. If in doubt, contact the manufacturer through their after-sales service.

Main photo: © ENSA